CONVERGING: How Cobots are Reshaping the Industry

In the context of the CONVERGING project COMAU, according to the specific requirements of the PRIMA end user about AM applications, introduced a new concept of cobot based on a medium payload robot enhanced with collaborative features able to offer an efficient solution in terms of technical and economic advantage as well as ease of use of the solution.

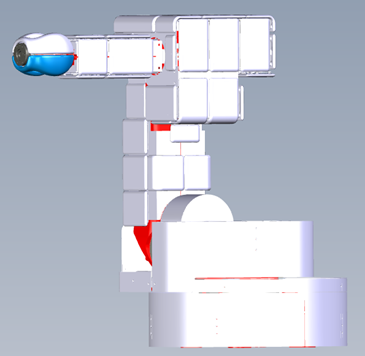

Starting from these main drivers, the approach foresaw the use of an industrial robot, namely the COMAU NJ60, with a payload of 60 kg and a reach of 2.2 m. The selection of such models started from the needs to cover the medium payload (and reach) segment guaranteeing the application in collaborative environments also where the request in terms of weight and operating space overpass the current solutions available in the market.

To include collaborative feature to the industrial COMAU NJ60, a specific commercial component has been introduced, the AIRSKIN safety pads: it is an add-on, modular safety solution to upgrade industrial robots and EoAT with pressure-sensitive sensors. The AIRSKIN pad is a soft, thin, airtight skin over a flexible dampening structure with safety electronics. Dual channel pressure sensors inside the hull detect pressure changes when the pad is deformed as the result of a contact anywhere on the pad surface. Each pad monitors correct operation by maintaining an internal overpressure of 400 pascal using an integrated piezo-electric micro pump. All pads are connected in series and monitor each other's presence every 4 ms. The skin's sensitivity is independent of the contact region, meaning regardless of where the operator come in contact with the AIRSKIN, the robot will go into safety rated protected stop. This occurs with 5 Newtons. AIRSKIN is equally effective for robots regardless of reach and payload.

After the selection of Robot model and collaborative technology to be applied, the design of a custom solution started with an iterative process between COMAU and the supplier to define the final design able to cover most of the safety aspects of the application with, as first output, some preliminary versions that have been conceived applying the standard pads offered by AIRSKIN to have a quantitative and qualitative feedback on the robot.

The design and manufacturing of the new prototype has been finalized and the final mounting is ongoing. After that a preliminary testing phase at laboratory environments will be setup replicating the conditions of the real industrial scenario. These activities will be expected to be finalized within July 2024.