The Future of Surface Treatments in Manufacturing: Robotics Trends

Surface treatment operations, such as polishing, painting, coating and others, play a critical role in manufacturing quality and product performance. Yet, despite decades of automation in machining, welding, and assembly, these processes remain among the most difficult to automate. As manufacturing faces increasing pressure from labor shortages, quality demands, and cost constraints, intelligent robotics is emerging as a key enabler for transforming surface treatments.

1. Why surface treatments are so difficult to automate

Unlike discrete manufacturing tasks, surface treatments require continuous contact with complex geometries. The robot must adapt in real time to variations in shape, surface condition, and material response.

Several factors contribute to this difficulty:

· Geometric variability: Real parts often deviate from their nominal geometry, especially after use, repair, or manual rework.

· Process sensitivity: Small changes in force, angle, or speed can significantly affect surface quality.

· Lack of digital references: CAD models are frequently unavailable or unreliable for repaired or legacy components.

· Human intuition: Skilled operators continuously adapt their motions based on visual and tactile feedback, capabilities that are challenging to encode in traditional robotic programs.

As a result, surface treatments have historically depended on manual labor, even in highly automated factories.

2. Structural challenges in manufacturing

The manufacturing industry is facing a growing labor challenge. Skilled workers capable of performing demanding manual tasks such as polishing or painting are becoming increasingly scarce.

Key structural issues include:

· An aging workforce, particularly in specialized trades.

· Low attractiveness of physically demanding and repetitive tasks for younger generations.

· Increasing training time required to reach acceptable quality levels.

· High dependency on individual expertise, making processes fragile and difficult to scale.

These challenges are not temporary. They represent a long-term trend that is forcing manufacturers to rethink how critical surface treatment operations are performed.

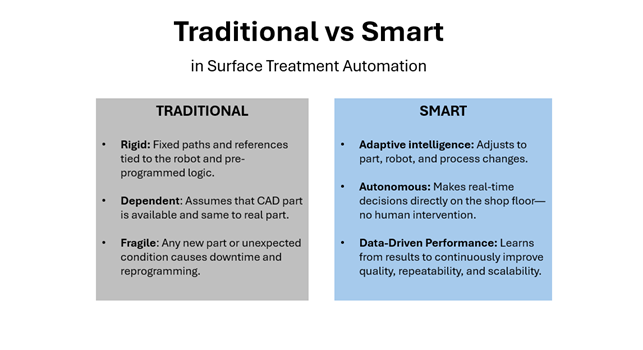

3. From traditional to smart

4. Transformative impact of Smart Robotics on surface treatments:

The adoption of smart robotics in surface treatment processes has far-reaching implications:

· Efficiency and Productivity: Robots can perform long, repetitive operations with consistent quality, reducing cycle times and freeing skilled workers to focus on higher-value tasks.

· Safety: Surface treatments often involve awkward postures, repetitive motions, dust, or chemical exposure. Robotics significantly reduces operator exposure to these hazards, improving workplace safety.

· Quantification and Traceability: By integrating sensors, such as force sensors, into the control loop, processes become measurable and repeatable. Parameters like applied force, contact time, and coverage can be recorded, enabling traceability and continuous improvement based on historical data.

· Flexibility and Scalability: Intelligent systems can adapt to new parts, geometries, or surface conditions with minimal reconfiguration. This flexibility is essential for industries characterized by short series, high variability, and frequent changes.

5. CONVERGING Automotive pilot

At TECNALIA, together with FORD, these challenges have driven the development of Watch and Work under the CONVERGING project, a technology framework designed to enable adaptive robotic operations for continuous-contact processes such as polishing in the automotive industry.

The automotive pilot, Watch and Work, combines real-time 3D perception, dynamic trajectory generation, and force-controlled execution, allowing robots to interact with real parts without relying on CAD models or complex part registration. The system is designed to behave more like a skilled operator: inspect first, then act, continuously adapting to what it “sees” and “feels.”

Recognizing the strategic potential of Watch and Work beyond individual projects, TECNALIA has committed internal funding to continue its development, mature the technology, and explore future exploitation paths.

Creators

Luis Valdés, TECNALIA Robotics Researcher